We are a team of professionals who understand what customers needs and we try to full fill those requirements in appropriate span of time with suitable prices.

We believe in “Supplying high quality products in the best prices”

We are pioneers in polymer concrete and epoxy resin, with semi automatic casting plant in Gujarat, we take our commitment to the international market seriously as 80% of our good goes into export making us an Indian company with significant global presence.

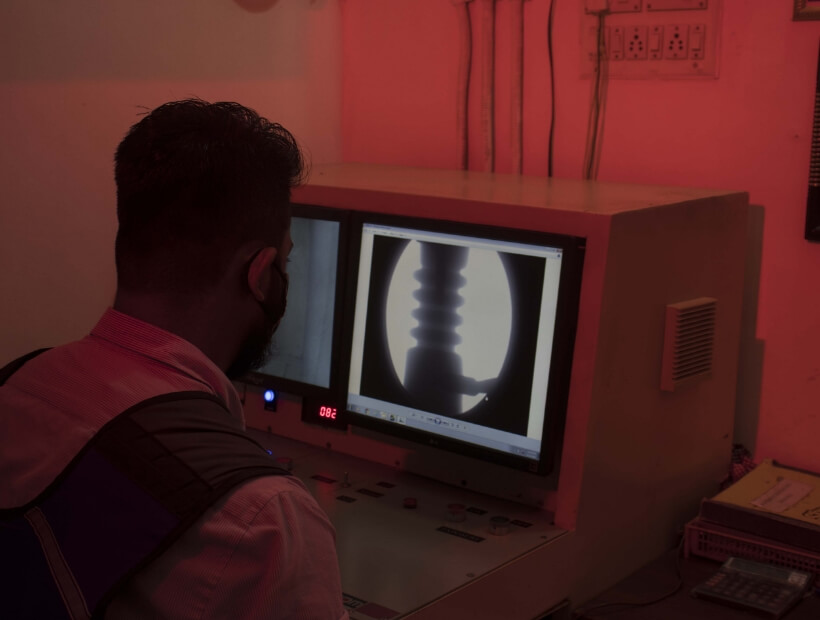

We believe in using the most cutting-edge technology to manufacture superior quality, reliable, and durable products for electrical application. Our production is based on the well proven technology of Automated Pressure Gelation (APG).

We take a special pride in our ability to create custom made epoxy component for, railway industries, distribution networks, switchgears and transformers industries in order to best meet the needs of our client.

At radiant you get a fast and professional solution from a single window and our team of experts and professionals engineers, together with our exceptional facilities and innovative technologies, ensures meticulous design and immaculate execution goes into every product we manufacture.

While always innovating and striving for advancement, we maintain the most competitive pricing. Our reputation in the region and always growing, loyal clientele speak for themselves.

Radiant is a company based on long-term growth orientation and we work with customer for the best possible solution.